Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How does the injection molding machine accurately and effectively control the barrel temperature?

The temperature control of the barrel of the injection molding machine is to use the microcomputer control loop to select the appropriate control algorithm to complete the control of the heating jackets outside the barrel of the injection molding machine. It is a very important indicator to ensure that the working temperature of each section in the barrel can be maintained within the set range according to the technical requirements.

The barrel temperature control object of the injection molding machine is a nonlinear, uncertain, strong coupling and large lag system, which is one of the control difficulties. For such objects, there is still a lack of a unified and effective control method, and the conventional PID control method cannot meet the requirements of high-precision injection.

The injection molding machine produces different products, the pre-plastic volume is different, the ambient temperature is different, and the barrel temperature object model parameters are different when the production cycle is different; there is a strong coupling phenomenon between the temperature control of each section of the barrel, and it is necessary to achieve complete temperature control. Decoupling control is very difficult; in addition, the object is a large-hysteresis system, and conventional control methods will inevitably have large overshoot and oscillation. Therefore, an adaptive temperature control strategy must be studied to achieve high-precision temperature.

In the process of plastic processing, temperature control mainly includes temperature control of barrel, nozzle and mold. The barrel temperature is the heating temperature of the barrel surface. Because the wall of the barrel is relatively thick, the selection of the thermocouple detection point is very critical, and the temperature curves of different detection points are quite different. Therefore, double-point parallel detection, that is, setting thermocouples on the surface and depth of the barrel at the same time, will obtain a relatively stable temperature curve, which is beneficial to the accuracy of temperature control.

The nozzle temperature directly affects the shear flow when the melt passes through, and has a great impact on the quality of the product, so the control accuracy of the nozzle temperature is higher. The mold temperature refers to the surface temperature of the mold cavity in contact with the product, which will significantly affect the mold filling, cooling and pressure holding processes.

Main Features:

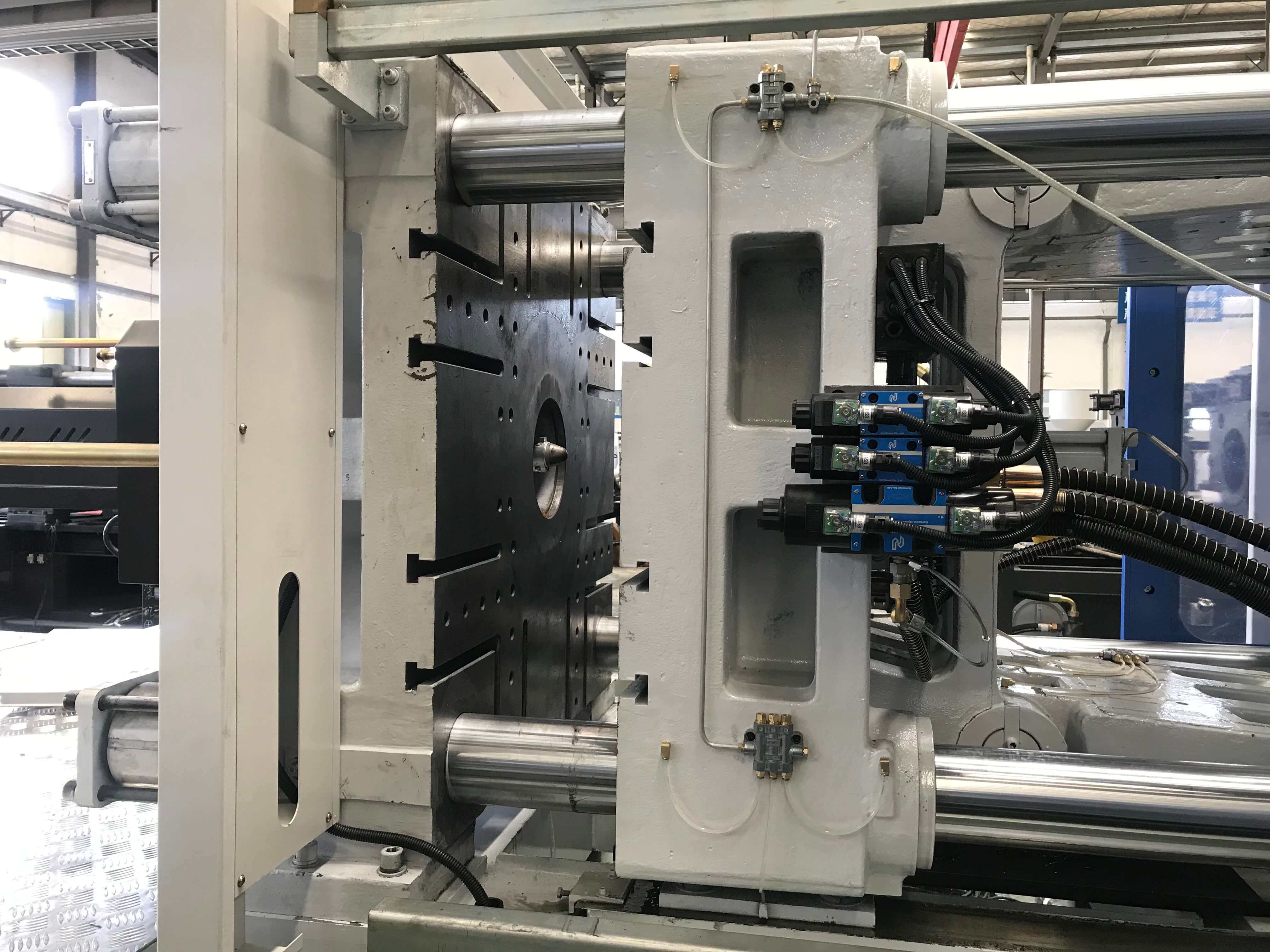

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.